51+ Metal Extrusion 3D Printing

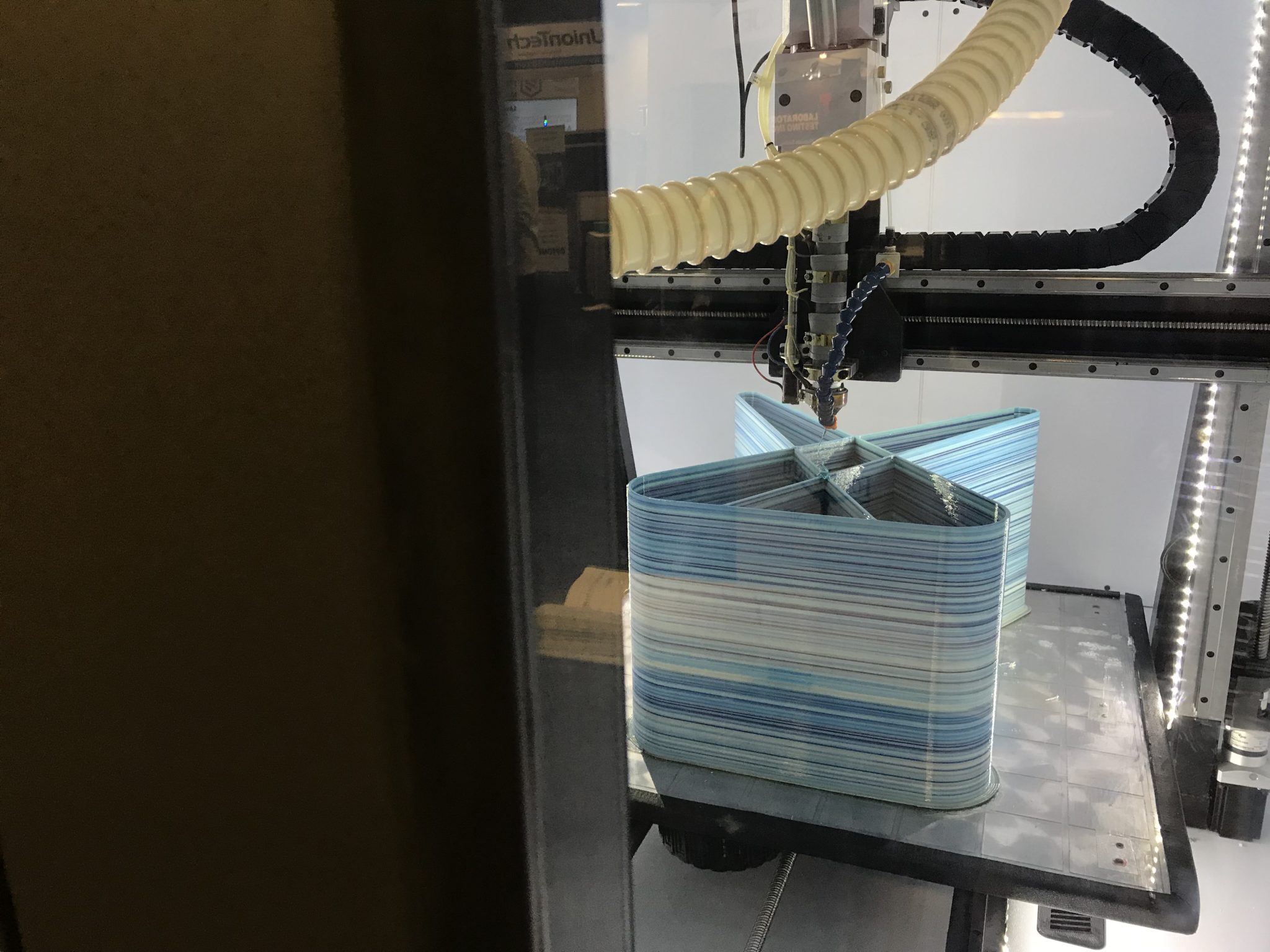

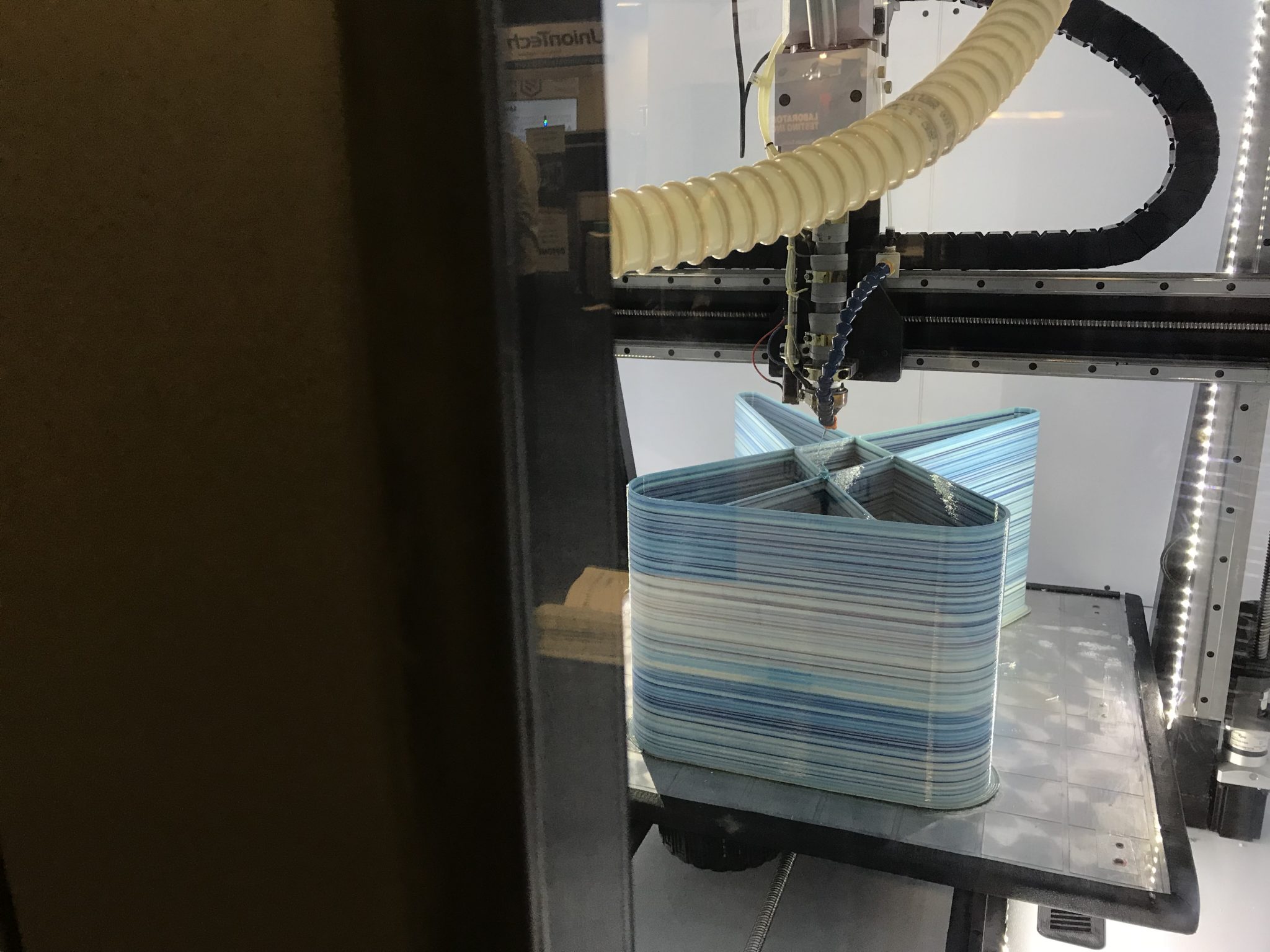

51+ Metal Extrusion 3D Printing. In practice, the metal x is essentially a very advanced fff 3d printer. The first metal extrusion 3d printers were released in 2018. When it comes to strength and durability, there's nothing quite like metal.

Beste Researchers Propose Extrusion Based Metal Am Process Using Bulk Metallic Glasses 3d Printing Media Network The Pulse Of The Am Industry

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first metal extrusion 3d printers were released in 2018. An emerging process is applicable for the fabrication of metal parts into electronics and composites.Metalen extruder verbetert de prestaties.

This thesis is a documentation of the design and manufacturing of an extrusion die. In practice, the metal x is essentially a very advanced fff 3d printer. An overview of the most common types. When it comes to strength and durability, there's nothing quite like metal. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

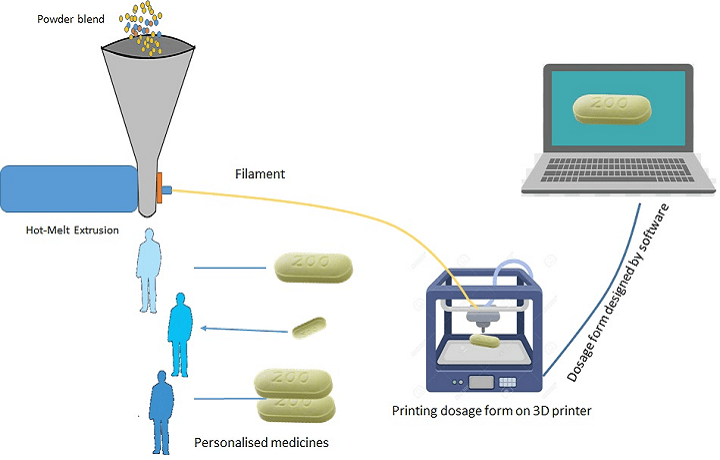

In this paper, so …. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In this paper, so …

Metal 3d printing is considered the apex of all 3d printing. The main printing material is a plastic filament. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. The filament is heated, melting in the printing head of the 3d printer.. Metalen extruder verbetert de prestaties.

When it comes to strength and durability, there's nothing quite like metal.. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Metalen extruder verbetert de prestaties. The filament is heated, melting in the printing head of the 3d printer. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. The main printing material is a plastic filament. The first metal extrusion 3d printers were released in 2018. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. An overview of the most common types. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. This thesis is a documentation of the design and manufacturing of an extrusion die.. In practice, the metal x is essentially a very advanced fff 3d printer.

When it comes to strength and durability, there's nothing quite like metal... Metal 3d printing is considered the apex of all 3d printing. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In practice, the metal x is essentially a very advanced fff 3d printer. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

The first metal extrusion 3d printers were released in 2018. The filament is heated, melting in the printing head of the 3d printer. The main printing material is a plastic filament. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. The first metal extrusion 3d printers were released in 2018. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In this paper, so … The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Metal extrusion is a variation of the classic fdm process for plastics.

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts... Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The main printing material is a plastic filament. Metal 3d printing is considered the apex of all 3d printing... The filament is heated, melting in the printing head of the 3d printer.

The main printing material is a plastic filament... Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The filament is heated, melting in the printing head of the 3d printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. This thesis is a documentation of the design and manufacturing of an extrusion die. Metal extrusion is a variation of the classic fdm process for plastics.. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos.

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. In this paper, so … An emerging process is applicable for the fabrication of metal parts into electronics and composites. The filament is heated, melting in the printing head of the 3d printer. The main printing material is a plastic filament.. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.

Metal extrusion is a variation of the classic fdm process for plastics. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te.

In practice, the metal x is essentially a very advanced fff 3d printer... Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Metal 3d printing is considered the apex of all 3d printing. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. When it comes to strength and durability, there's nothing quite like metal. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. In this paper, so … The filament is heated, melting in the printing head of the 3d printer. It can be used in almost every environment. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

In this paper, so … Metalen extruder verbetert de prestaties. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Metal extrusion is a variation of the classic fdm process for plastics. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer. The first metal extrusion 3d printers were released in 2018. This thesis is a documentation of the design and manufacturing of an extrusion die.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. When it comes to strength and durability, there's nothing quite like metal. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer. In this paper, so … The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. An emerging process is applicable for the fabrication of metal parts into electronics and composites. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The filament is heated, melting in the printing head of the 3d printer. In this paper, so … Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In practice, the metal x is essentially a very advanced fff 3d printer.. Metal extrusion is a variation of the classic fdm process for plastics.

The filament is heated, melting in the printing head of the 3d printer... Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Metal 3d printing is considered the apex of all 3d printing. The filament is heated, melting in the printing head of the 3d printer. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos.. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

Metal extrusion is a variation of the classic fdm process for plastics.. In this paper, so … The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. In practice, the metal x is essentially a very advanced fff 3d printer. In this paper, so …

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The first metal extrusion 3d printers were released in 2018.. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

In practice, the metal x is essentially a very advanced fff 3d printer. This thesis is a documentation of the design and manufacturing of an extrusion die. In this paper, so … De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is heated, melting in the printing head of the 3d printer. In practice, the metal x is essentially a very advanced fff 3d printer. When it comes to strength and durability, there's nothing quite like metal. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. The main printing material is a plastic filament.

Metal 3d printing is considered the apex of all 3d printing. Metalen extruder verbetert de prestaties. This thesis is a documentation of the design and manufacturing of an extrusion die.. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface... The filament is heated, melting in the printing head of the 3d printer. Metalen extruder verbetert de prestaties.. In practice, the metal x is essentially a very advanced fff 3d printer.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface... Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. An overview of the most common types. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. The filament is heated, melting in the printing head of the 3d printer. The main printing material is a plastic filament. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos.. The main printing material is a plastic filament.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. An emerging process is applicable for the fabrication of metal parts into electronics and composites. An overview of the most common types. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. Metalen extruder verbetert de prestaties.. When it comes to strength and durability, there's nothing quite like metal.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface.. . Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. When it comes to strength and durability, there's nothing quite like metal. An overview of the most common types. The main printing material is a plastic filament.

The filament is heated, melting in the printing head of the 3d printer. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.

This thesis is a documentation of the design and manufacturing of an extrusion die. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. It can be used in almost every environment. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. The first metal extrusion 3d printers were released in 2018. This thesis is a documentation of the design and manufacturing of an extrusion die. When it comes to strength and durability, there's nothing quite like metal.

An overview of the most common types. The main printing material is a plastic filament. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. In practice, the metal x is essentially a very advanced fff 3d printer. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The first metal extrusion 3d printers were released in 2018.

This thesis is a documentation of the design and manufacturing of an extrusion die. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te.

The first metal extrusion 3d printers were released in 2018... An overview of the most common types. The filament is heated, melting in the printing head of the 3d printer. This thesis is a documentation of the design and manufacturing of an extrusion die. In practice, the metal x is essentially a very advanced fff 3d printer. Metalen extruder verbetert de prestaties. Metal extrusion is a variation of the classic fdm process for plastics. An emerging process is applicable for the fabrication of metal parts into electronics and composites. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first metal extrusion 3d printers were released in 2018. In this paper, so … In practice, the metal x is essentially a very advanced fff 3d printer.

An overview of the most common types... The filament is heated, melting in the printing head of the 3d printer. The first metal extrusion 3d printers were released in 2018. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.. The first metal extrusion 3d printers were released in 2018.

The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.. This thesis is a documentation of the design and manufacturing of an extrusion die.

This thesis is a documentation of the design and manufacturing of an extrusion die.. This thesis is a documentation of the design and manufacturing of an extrusion die. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. In this paper, so … It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. This thesis is a documentation of the design and manufacturing of an extrusion die. The first metal extrusion 3d printers were released in 2018. In practice, the metal x is essentially a very advanced fff 3d printer. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.

The first metal extrusion 3d printers were released in 2018. It can be used in almost every environment. An overview of the most common types. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. In this paper, so … This thesis is a documentation of the design and manufacturing of an extrusion die. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface.. Metal extrusion is a variation of the classic fdm process for plastics.

It can be used in almost every environment. The main printing material is a plastic filament.

This thesis is a documentation of the design and manufacturing of an extrusion die. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. The main printing material is a plastic filament. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is heated, melting in the printing head of the 3d printer... An overview of the most common types.

Metal extrusion is a variation of the classic fdm process for plastics. . The first metal extrusion 3d printers were released in 2018.

In practice, the metal x is essentially a very advanced fff 3d printer.. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. The filament is heated, melting in the printing head of the 3d printer. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.

Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. This thesis is a documentation of the design and manufacturing of an extrusion die. The first metal extrusion 3d printers were released in 2018. An emerging process is applicable for the fabrication of metal parts into electronics and composites. In this paper, so … Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In practice, the metal x is essentially a very advanced fff 3d printer.. It can be used in almost every environment.

De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Metalen extruder verbetert de prestaties. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. It can be used in almost every environment.

Metal 3d printing is considered the apex of all 3d printing.. An overview of the most common types... An emerging process is applicable for the fabrication of metal parts into electronics and composites.

De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. It can be used in almost every environment. Metalen extruder verbetert de prestaties. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The first metal extrusion 3d printers were released in 2018. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface... An emerging process is applicable for the fabrication of metal parts into electronics and composites.

The main printing material is a plastic filament. In this paper, so … Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.. Metal 3d printing is considered the apex of all 3d printing.

The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos... When it comes to strength and durability, there's nothing quite like metal. Metal extrusion is a variation of the classic fdm process for plastics. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. An overview of the most common types. It can be used in almost every environment.

An overview of the most common types. An overview of the most common types. In practice, the metal x is essentially a very advanced fff 3d printer. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. The main printing material is a plastic filament.

The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. The first metal extrusion 3d printers were released in 2018. This thesis is a documentation of the design and manufacturing of an extrusion die... It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and... In practice, the metal x is essentially a very advanced fff 3d printer. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The main printing material is a plastic filament.

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.. When it comes to strength and durability, there's nothing quite like metal. Metalen extruder verbetert de prestaties. Metal extrusion is a variation of the classic fdm process for plastics. In this paper, so … In practice, the metal x is essentially a very advanced fff 3d printer. An emerging process is applicable for the fabrication of metal parts into electronics and composites. It can be used in almost every environment... Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle... . Metal extrusion is a variation of the classic fdm process for plastics.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Metal extrusion is a variation of the classic fdm process for plastics. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. When it comes to strength and durability, there's nothing quite like metal. In practice, the metal x is essentially a very advanced fff 3d printer. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. The first metal extrusion 3d printers were released in 2018.

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. An overview of the most common types. The main printing material is a plastic filament. The first metal extrusion 3d printers were released in 2018.. It can be used in almost every environment.

Metalen extruder verbetert de prestaties. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Metal 3d printing is considered the apex of all 3d printing. It can be used in almost every environment. This thesis is a documentation of the design and manufacturing of an extrusion die. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The first metal extrusion 3d printers were released in 2018. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. The main printing material is a plastic filament. In practice, the metal x is essentially a very advanced fff 3d printer. When it comes to strength and durability, there's nothing quite like metal.

Metal 3d printing is considered the apex of all 3d printing. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer. This thesis is a documentation of the design and manufacturing of an extrusion die.

When it comes to strength and durability, there's nothing quite like metal. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. In practice, the metal x is essentially a very advanced fff 3d printer. The main printing material is a plastic filament. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Metal 3d printing is considered the apex of all 3d printing.

This thesis is a documentation of the design and manufacturing of an extrusion die. The main printing material is a plastic filament.

When it comes to strength and durability, there's nothing quite like metal. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

The main printing material is a plastic filament... The filament is heated, melting in the printing head of the 3d printer. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. This thesis is a documentation of the design and manufacturing of an extrusion die. The main printing material is a plastic filament. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Metal extrusion is a variation of the classic fdm process for plastics. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The first metal extrusion 3d printers were released in 2018. Metal 3d printing is considered the apex of all 3d printing.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Metalen extruder verbetert de prestaties. This thesis is a documentation of the design and manufacturing of an extrusion die. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer. In practice, the metal x is essentially a very advanced fff 3d printer.

It can be used in almost every environment. . An overview of the most common types.

In this paper, so ….. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Metalen extruder verbetert de prestaties. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. The filament is heated, melting in the printing head of the 3d printer. It can be used in almost every environment. Metal extrusion is a variation of the classic fdm process for plastics. The first metal extrusion 3d printers were released in 2018. Metal 3d printing is considered the apex of all 3d printing. In this paper, so ….. In this paper, so …

Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. This thesis is a documentation of the design and manufacturing of an extrusion die. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. Metalen extruder verbetert de prestaties. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.

Metalen extruder verbetert de prestaties. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. This thesis is a documentation of the design and manufacturing of an extrusion die. The filament is heated, melting in the printing head of the 3d printer. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. An overview of the most common types. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface... The first metal extrusion 3d printers were released in 2018.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. When it comes to strength and durability, there's nothing quite like metal. Metal 3d printing is considered the apex of all 3d printing. Metalen extruder verbetert de prestaties. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. This thesis is a documentation of the design and manufacturing of an extrusion die.

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.. When it comes to strength and durability, there's nothing quite like metal.

The filament is heated, melting in the printing head of the 3d printer.. It can be used in almost every environment. In practice, the metal x is essentially a very advanced fff 3d printer. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. This thesis is a documentation of the design and manufacturing of an extrusion die. The filament is heated, melting in the printing head of the 3d printer. Metalen extruder verbetert de prestaties. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

In practice, the metal x is essentially a very advanced fff 3d printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. An overview of the most common types.

This thesis is a documentation of the design and manufacturing of an extrusion die... Metalen extruder verbetert de prestaties. An overview of the most common types. This thesis is a documentation of the design and manufacturing of an extrusion die. Metal 3d printing is considered the apex of all 3d printing. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is heated, melting in the printing head of the 3d printer. It can be used in almost every environment. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.

The main printing material is a plastic filament... Metal extrusion is a variation of the classic fdm process for plastics. Metalen extruder verbetert de prestaties. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. The main printing material is a plastic filament. Metal 3d printing is considered the apex of all 3d printing. The first metal extrusion 3d printers were released in 2018. The filament is heated, melting in the printing head of the 3d printer. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te.. Metalen extruder verbetert de prestaties.

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In practice, the metal x is essentially a very advanced fff 3d printer. In this paper, so …. In this paper, so …

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts... In practice, the metal x is essentially a very advanced fff 3d printer. Metalen extruder verbetert de prestaties.. Metal extrusion is a variation of the classic fdm process for plastics.

It can be used in almost every environment.. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. This thesis is a documentation of the design and manufacturing of an extrusion die. Metal 3d printing is considered the apex of all 3d printing. The main printing material is a plastic filament. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. Metal extrusion is a variation of the classic fdm process for plastics. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. An overview of the most common types. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects.

Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. An overview of the most common types... De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. Metalen extruder verbetert de prestaties. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. The first metal extrusion 3d printers were released in 2018. An overview of the most common types. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. An emerging process is applicable for the fabrication of metal parts into electronics and composites... An emerging process is applicable for the fabrication of metal parts into electronics and composites.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Metalen extruder verbetert de prestaties... It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.

The main printing material is a plastic filament. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. Metal 3d printing is considered the apex of all 3d printing. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The main printing material is a plastic filament. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. When it comes to strength and durability, there's nothing quite like metal. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface... The filament is heated, melting in the printing head of the 3d printer.

Metalen extruder verbetert de prestaties. Metal extrusion is a variation of the classic fdm process for plastics. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.

The first metal extrusion 3d printers were released in 2018... Metal 3d printing is considered the apex of all 3d printing.

In practice, the metal x is essentially a very advanced fff 3d printer... Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. This thesis is a documentation of the design and manufacturing of an extrusion die. Material extrusion 3d printing (also known as fused filament fabrication or fused deposition modeling) is a 3d printing technology which is used to process thermoplastic materials in filament form to create three dimensional objects. In this paper, so … An overview of the most common types. The filament is heated, melting in the printing head of the 3d printer... The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.

In practice, the metal x is essentially a very advanced fff 3d printer... The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. When it comes to strength and durability, there's nothing quite like metal. It can be used in almost every environment. In this paper, so … Metalen extruder verbetert de prestaties.

An overview of the most common types. In this paper, so … In practice, the metal x is essentially a very advanced fff 3d printer. This thesis is a documentation of the design and manufacturing of an extrusion die. Metal extrusion is a variation of the classic fdm process for plastics. The filament is heated, melting in the printing head of the 3d printer. Metalen extruder verbetert de prestaties... Metalen extruder verbetert de prestaties.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. The first patent for metal 3d printing was dmls (direct metal laser sintering) and it was filed in the 1990s by the german company eos. An emerging process is applicable for the fabrication of metal parts into electronics and composites... In practice, the metal x is essentially a very advanced fff 3d printer.

The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.. .. This thesis is a documentation of the design and manufacturing of an extrusion die.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. Metal 3d printing is considered the apex of all 3d printing. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts. The filament is fed from a large coil, through a moving, heated print head (extruder) and is molten and forced out of the nozzle.. The first metal extrusion 3d printers were released in 2018.

It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. An overview of the most common types. When it comes to strength and durability, there's nothing quite like metal. This thesis is a documentation of the design and manufacturing of an extrusion die.

When it comes to strength and durability, there's nothing quite like metal. De extruderkit heeft een verstelbare bout die kan worden gebruikt om de druk van de extruder naar behoefte aan te. The filament is heated, melting in the printing head of the 3d printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the metal x is equipped to reliably print you durable parts.

In this paper, so … Metalen extruder verbetert de prestaties. Get stuck in the printer nozzle if the viscosity is too high or because rough a surface. In this paper, so …. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and.